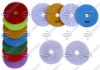

Product Features:

felt wheels

high Performance/Price Ratio and , good brightness, high cutting

Business Terms:

Port: tianjin port

Minimum Order Quantity: 50 Piece/Pieces

Supply Ability: 10000 Piece/Pieces per Month

Payment Terms: L/C,T/T

Contact Supplier