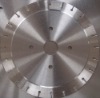

PDC cutters consist of PCD layer integrally sintered at ultrahigh pressure and high temperature to a cemented tungsten carbide backing. They have high hardness, wear(abrasion) resistance and impact resistance, are widely used for oil/gas drilling, geology exploration and mining, applied to soft to medium hard formations. And also could be used be on some grinding tools and wear resistant parts.

The standard shape is cylinder, we can also supply the PCD cutters in all kinds of shapes (square, rectangle, triangle, sector, etc.) with diameter from 4 to 25mm, PCD layer from 0.3 to 3mm,the total height from 1.0 to 25mm.Other size and shapes could be made as your requirement.

Our PDC cutter included three series:

A.PDC cutter used in oil/gas drilling,

B.PDC cutter used in geology exploration, rock drilling and mining

C.PDC/PCD cutter used in grinding and polishing

PDC (Polycrystalline Diamond Compact) cutters

| Specifications | 0808 | 1004 | 1008 | 1304 | 1308 | 1313 | 1608 | 1613 | 1616 | 1908 | 1913 | 1916 | 1919 |

| Diameter(mm) | 8.20 | 10.00 | 10.00 | 13.30 | 13.44 | 13.44 | 16.00 | 16.00 | 16.00 | 19.05 | 19.05 | 19.05 | 19.05 |

| Height( mm) | 8.00 | 4.00 | 8.00 | 4.50 | 8.00 | 13.20 | 8.00 | 13.20 | 16.00 | 8.00 | 13.20 | 16.00 | 19.00 |

Non-standard could be made as your request.

Advantage of polycrystalline diamond compact PDC cutter

A. Selected higher quality diamond powder, improved the sintering technique, enhanced the bond combination strength between diamond grain

B.Improved the inner structure of the sintered cavity, the pressure and temperature become more balance, which ensure the cutter has more stable performance

C.Adopted a new type of carbide, which improved the weld strength

D.Optimized the designation of joint face, which reduced the residual stress